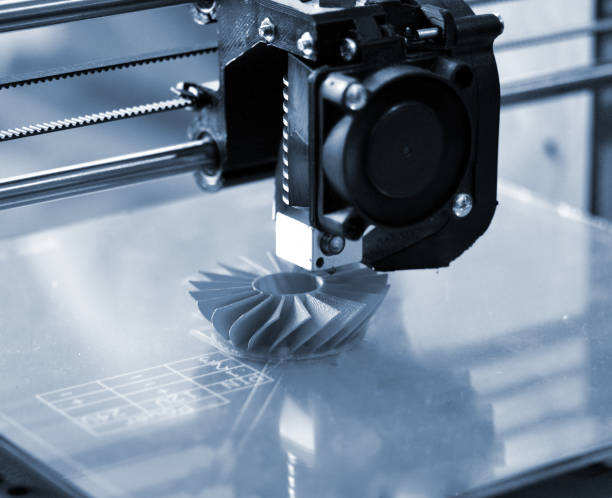

Additive manufacturing is the process of creating a three-dimensional object by adding material layer by layer. This process has been used for many years in industries such as aerospace and automotive to create prototypes and end-use parts. In recent years, additive manufacturing has become more popular for producing small quantities of parts or “one-offs.” One area where additive manufacturing is starting to be used more often is in the production of heat exchangers. In this blog post, we will discuss titanium additive manufacturing and how it is being used to produce 3D printed heat exchangers.

Titanium is a strong, lightweight metal that is resistant to corrosion and has a high melting point. These properties make titanium an ideal material for use in additive manufacturing. Titanium additive manufacturing (AM) is a process of using titanium powder to build parts layer by layer. This process offers many benefits over traditional manufacturing methods, such as the ability to create complex geometries and the ability to produce parts with very precise dimensions.

Companies are using titanium AM to produce heat exchangers. These companies are leader in the development and production of 3D printed titanium components for aerospace and industrial applications. Companies has developed a unique process for producing 3d printed heat exchanger that can be used in a variety of applications, such as cooling aircraft engines and power generation plants.

Titanium AM process starts with a titanium powder that is placed in a build chamber. The powder is then melted with a laser and deposited onto a build platform. The layer of titanium is then cooled and the next layer is deposited on top. This process is repeated until the desired geometry is achieved. Once the heat exchanger has been printed, it undergoes a series of post-processing steps, such as machining and surface finishing, to prepare it for use in its intended application.

Titanium additive manufacturing offers many benefits over traditional manufacturing methods. The ability to create complex geometries and produce parts with very precise dimensions makes titanium AM an attractive option for the production of heat exchangers. In addition, titanium AM is a much faster process than traditional manufacturing methods and can be used to produce small quantities of parts or “one-offs.”

If you are in the market for a 3D printed titanium heat exchanger, titanium 3d printing should be your first choice. Unique titanium AM process and commitment to quality make it the perfect partner for your additive manufacturing needs.